A valuable application for shredded composite material from wind turbine blades

Jan 2018 - ongoing

The product creates a symbolic link with the wind energy industry and anticipates on the energy suppliers, who own the wind turbines, by recycling the material into a product they offer.

By Tjits Tuinhof

The wind energy industry is growing significantly, which increases the number of decommissioned wind turbines as well. The blades of wind turbines are mainly made of fiber reinforced thermoset polymer composite, which is difficult to recycle. Most blades currently end up in landfill or incineration which is a waste of this high value material. In this project, a valuable application for mechanically recycled composite material is designed, which will ensure the wind turbine blades of an end-of-life situation that fits within the circular economy.

Material research is executed to get a grip on the characteristics of the shredded composite. These specific characteristics are eventually used to generate ideas on valuable applications for the material in which the recyclate is a wanted addition, instead of a disturbance. Based on the formulated vision, requirements and wishes, an electrical car charger is selected as the best suitable idea.

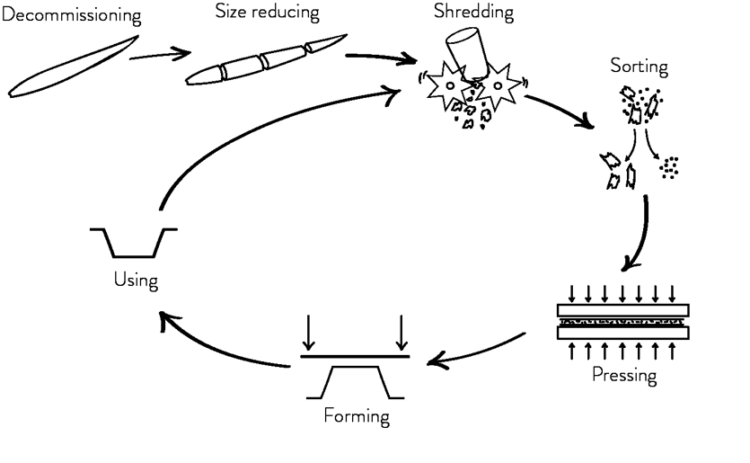

This product demonstrates how the shreds can be reused in a thermoplastic material. It has a symbolic link with the wind energy industry and anticipates on the energy suppliers, who own the wind turbines, by recycling the material into a product they offer.The electrical charger is produced by pressing the shredded composite between two sheets of thermoplastic material and shaping this with vacuum forming. After its use, the product can be again recycled into new applications.

However, the shredded composite will be part of a cascading model in which the fiber size will decrease with every recycling procedure. The design is only reusing a small amount of the total supply of composite waste and is therefore not an all-encompassing solution to the problem. Additionally, mechanical recycling does cause significant down-cycling of the high value material. Therefore, it is best to replace the thermoset polymer composites with a better recyclable material, until a recycling procedure turning the fibers and resin back into raw materials is fully developed.

To find more information about the project you can click here

Supervisory Team

Kaspar Janser – Chair

Jelle Joustra – Mentor