Recycling wind turbine blades: pyrolysis of glass fibre reinforced composites

Sep 2018 - ongoing

Environmental benefits of pyrolysis of glass fibre reinforced composites from EoL wind turbine blades (WTB)

By Julia Koelega

Driven by the energy transition from fossil fuels to renewable energy sources aimed at mitigating global warming, the wind energy industry has increased significantly in the past decades. Until now, most research on renewable energy production is concentrated on increased efficiency and capacity and less attention is paid to possible secondary effects of the renewable energy production.

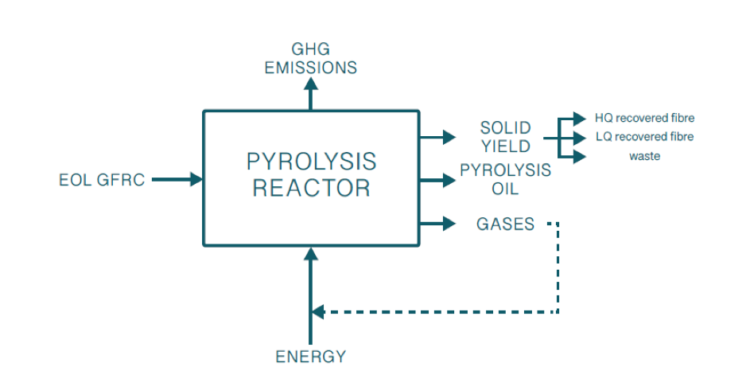

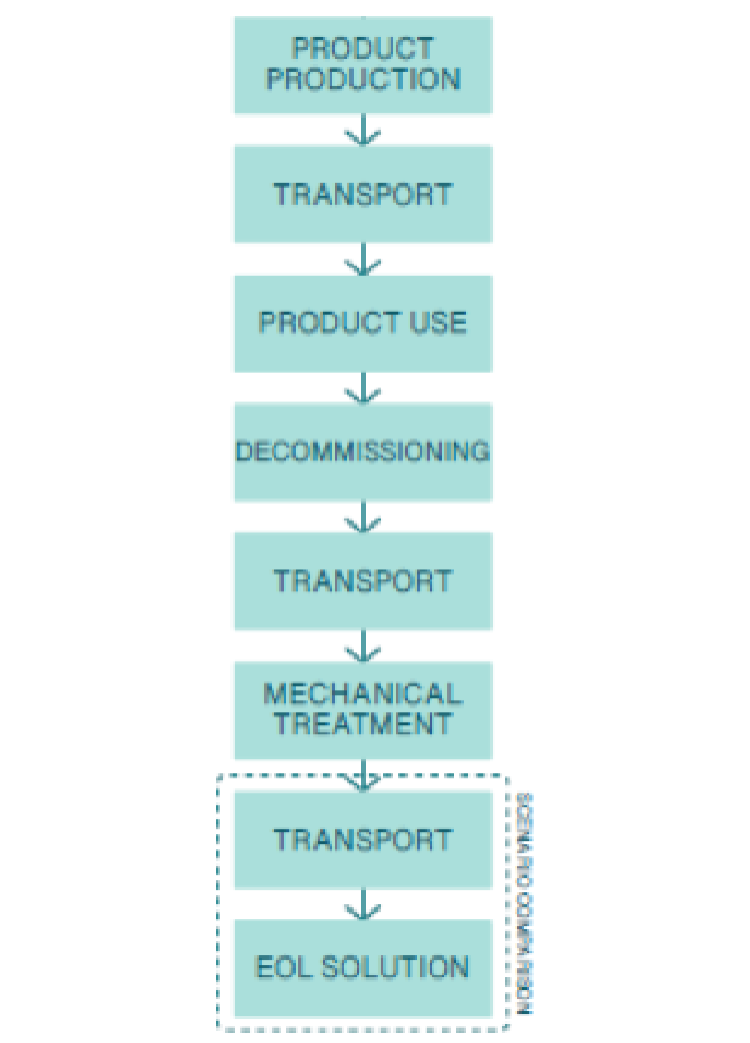

The composite waste from wind turbine blades is becoming an increasingly important environmental issue for which innovative end-of-life (EoL) solutions are needed. This study aims to investigate to what extent the recycling of glass fibre reinforced composites from EoL wind turbine blades (WTB) by the means of a pyrolysis process can create environmental benefits within the context of the Port of Rotterdam (PoR) in the coming 5 to 10 years.

An explorative study provided a better understanding of the concepts based on combination of academic knowledge (desk study) and practical experiences (field study) and was used to define three hypothetical EoL scenarios for WTB including landfill, cement-kiln and pyrolysis.

A comparison analysis considering these scenarios showed that pyrolysis could deliver both environmental and economic benefits, providing that the majority of the pyrolysis products find high- value secondary applications and that the combustion of the pyrolysis oil as fuel oil is avoided.

Although the extent of the environmental benefits that could be created by the implementation of pyrolysis remain uncertain, the presented results indicate that pyrolysis could form an early step in a larger, long- term transitional movement towards a carbon-neutral and circular economy. Based on these findings the PoR is recommended to adopt a participating or pioneering role in this transition, enabling technology optimization for pyrolysis and investing in cooperation with a network of (future) stakeholders.

To find more information about this project you can click here

Supervisory Team

René Kleijn – Graduation committee

Ruud Balkenende – Mentor

Jelle Joustra – Daily supervisor