Reduction of harmful noise pollution during hip replacement surgery

Jan 2020 - ongoing

This graduation project was done on behalf of TU Delft and Zimmer Biomet in collaboration with Orthopedic surgeons from Bergman Clinics, Orthopedic Clinic, in Naarden. The aim of this project was to design a product solution which could reduce the pollution of harmful noise during hip replacement surgery. For Critical Alarms Lab, this project was the first project out of the ICU and into the OR, broadening the Lab’s scope and research environments.

The operating theatre..

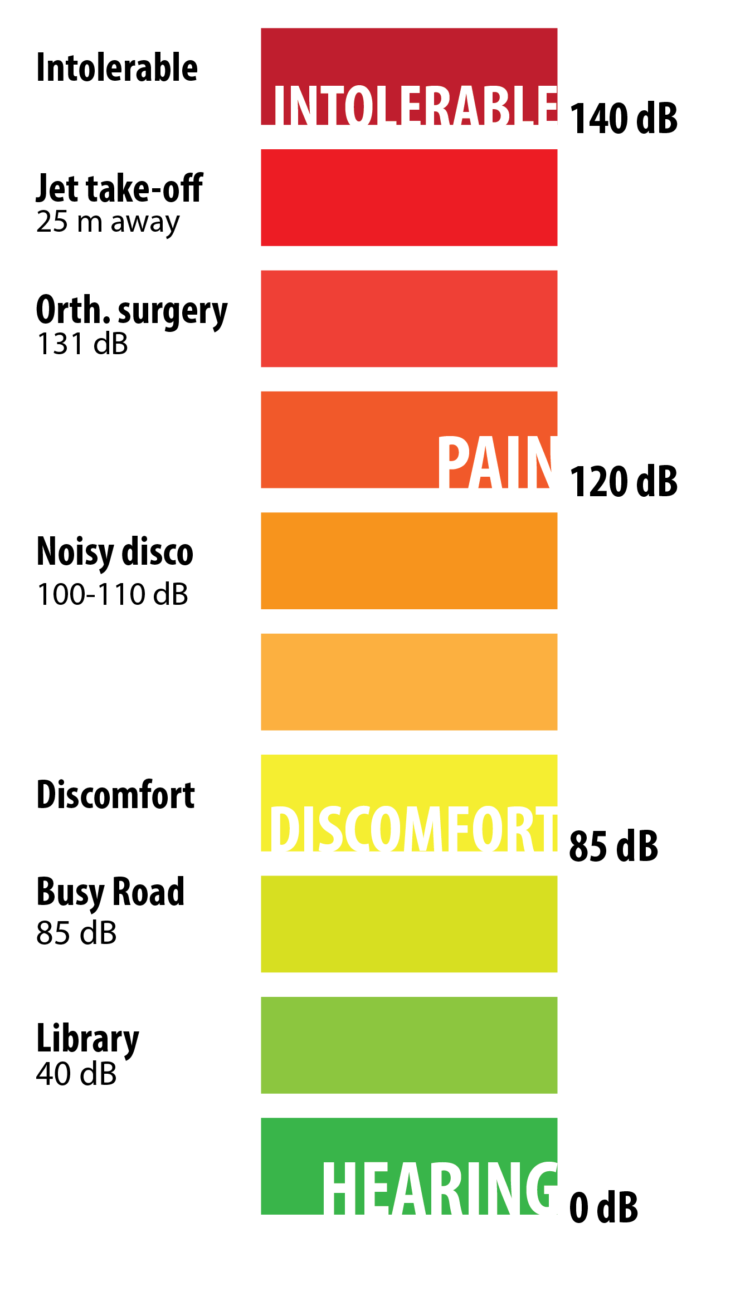

In orthopedic surgery and hip replacement surgery in general high sound levels are reached due to the usage of (powered) surgical instruments. Noise levels can reach up to 130 dB and may cause permanent noise-induced hearing loss.

As Noise-induced hearing loss may be temporary during surgery, it could become permanent, resulting in requiring hearing aid and may be accompanied by tinnitus. In research, was found that 50% of orthopedic personnel with long-term exposure to power instruments showed early signs of hearing loss. The challenge of doing something about the noise is that sound is important to surgeon and staff, as they use sound as feedback to validate successful implantation of joint components.

In the current procedure of total hip arthroplasty (THA) a surgical mallet is used in most of the surgical steps. This instrument gets used to impact implants into the bone by hitting impactor tools or handles where the implants/tools are attached to. The metal-on-metal impact causes large sound peaks of more than 120 dB, above the human pain threshold. Sound peaks of these magnitudes will cause short term hearing loss, what affects communication during surgery. Longtime exposure to these peaks can even result in permanent (long-term) hearing loss.

More than a sound problem..

The current precaution for high sound levels is to wear hearing protection, but this can block the necessary feedback and subsequently results in a loss of communication. Additionally, hospital masks and sterile operating suits already negatively affect verbal communication. To conclude staff, tends not to use hearing protectors as it disconnects them from their environment and hinders auditory information being communicated correctly. Adding to this, that miscommunication is one of the most blamed factors resulting in medical errors and poor patient outcomes.

In addition to the sound levels reached, the tools used during surgery are valued as high-risk factors concerning labor safety and working postures, which increase the surgeon’s risk for injury followed by potential absenteeism. Two out of 3 orthopedic surgeons have work related injuries, which leads to a surgeon absenteeism (7.3 days on average), which costs healthcare institutions large sums of money (revenue loss of approx. $100K), but even more important it increases patient waiting time and postponement of required surgery and patient care.

In that sense, both sound and the usage of noise emitting instruments are a deteriorating factor for the healthcare provided with high economic and healthcare implications for institutions, hospitals and patients.

New surgical instrument..

The outcome of this project is a new surgical instrument*, which can implant various hip joint replacement components during surgery. The instrument has multiple unique selling points compared to the currently used products as it reduces the noise level with more than 15 decibels and is scores better on aspects of safety when looking into the risks for musculoskeletal disorders and improved surgical ergonomics.

*as this graduation project and design solution are placed under embargo, no information on the design and conclusions can be provided.