Toward Textile-form Futures

Nov 2023 - ongoing

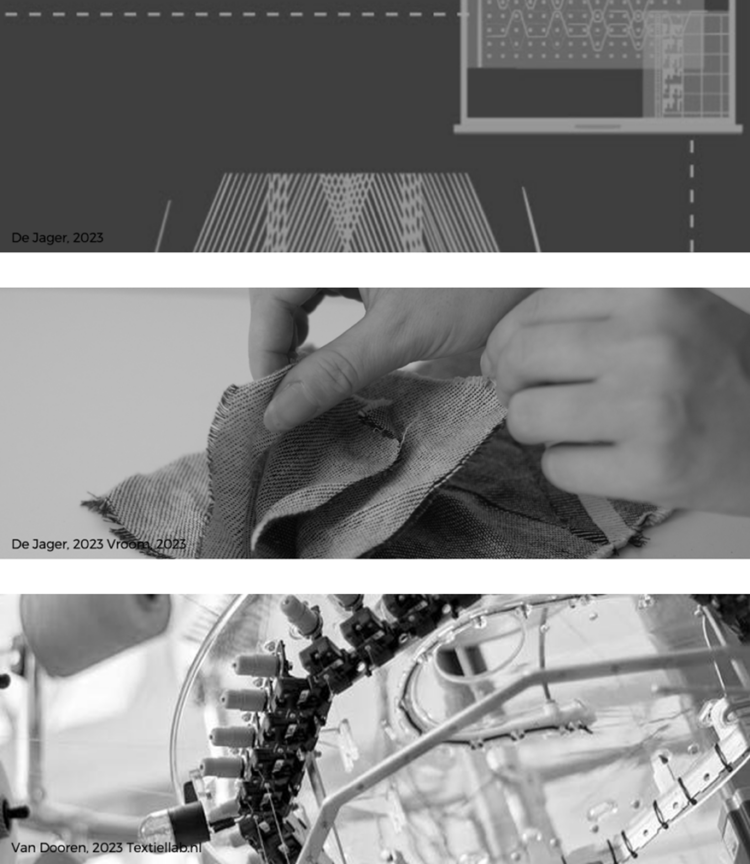

Textile-forms are textile-based objects that are made via the simultaneous construction of textile and form, which enable on-demand and local production of textile-based consumer products to reduce the industry’s severe climate impacts. How can the future of textile-forms from design, manufacturing, and systems perspectives be explored to develop this vision in the Dutch and Greater Rotterdam Region?

The textile/fashion industry is one of the most polluting, least automated and manual-labour dependent industries in the world – contributing 10% of GHG emissions. Our current systems of design, production, and use are no longer fit for purpose, and resistant to systems-level change. It is imperative we take responsibility for these impacts, but to do so requires vision, innovation and collaboration. Imagine a future where all textile-based products can be ordered and produced locally, on-demand, in waste and pollution-free, semi/fully automated micro-factories. Where local waste fibers can be processed locally, virgin fibers are safely produced using regenerative agriculture methods, and systems are designed from the outset for and with circularity.

The project’s ambition is to develop a strategy toward a local exemplar of circular textile-form systems – such as an integrated circular micro-factory – that will be the foundation for the development of larger funding applications to explore relevant localised models of production across Europe. This strategy includes network development, preliminary methods, models, and prototypes for textile-form suitable for localised and on-demand production of textile-based products within the Dutch and Greater Rotterdam Region context. In the long term, the project seeks to enhance societal resilience by facilitating sustainable, comfortable, adaptable textile options for end users, while stimulating sustainability innovation in the local textile industry.

Designing industry transitions

PCM Lab researcher Ir. Sterre de Jager is actively engaged in the project, mainly alongside Dr. Holly McQuillan (TUD) and Dr. Mariangela Lavanga (EUR). Together, they are investigating the feasibility of developing a local circular textile model within the Greater Rotterdam Region: designing industry transitions.

In light of recently upcoming and enforced regulations on Extended Producer Responsibility and recycling obligations, both brands and recycling facilities are under increasing pressure to transition towards localized circular systems. Consequently, plans are being made, particularly in the Greater Rotterdam Region, to establish a Circular Textile Hub focused on optimizing the sorting and recycling of discarded textiles. Although these initiatives signify positive developments, as far as the project team knows, there is not yet a fully successful circular model at a local or regional scale in the Netherlands, encompassing the entire lifecycle—from fiber growth and processing to spinning, production, distribution, consumer use, collection, sorting, recycling, and subsequent repetition of the cycle.

The goal is to apply innovative design-manufacturing methods towards systemic change. These methods demonstrate great potential for on-demand, made-to-measure, and small-scale clothing production. However, as prior research has shown, this can only be put to good use if we move towards a fully closed, local model, which the project is actively exploring in the Greater Rotterdam Region.

Sterre de Jager is currently mapping key systemic stakeholders in the region and beyond for potential partnerships, knowledge exchange, and co-creation. Thereby establishing a national and international network of experts in the field of fibre processing (Zoe Gilbertson), fashion anthropology (Dr. Sandra Niessen), waste management and more. Other contributors include the Plastic Soup Foundation, Zeeman, Fibershed NL, and various clothing brands and designers within the Rotterdam region. Co-creation sessions will take place with these experts, complemented by a co-creative session involving experts and students from TUD and EUR. The project is working open-source and seeks to include artisanal practices where possible.

An inter- and transdisciplinary team

Toward Textile-form Futures embraces a transdisciplinary approach, inviting collaboration with experts from various fields including spatial/urban planning, sustainability transition in fashion and textiles, creative entrepreneurship, circular economy, textile engineering, garment/form design, and computational design. The team consists of Assist. Prof., Dr Holly McQuillan (TUD), Assoc. Prof., Dr Mariangela Lavanga (EUR), researcher Ir. Sterre de Jager (TUD), PhD candidate Milou Voorwinden, MA (TUD), and TU/d graduation students Sem Janssen, Savanne Klop and (soon to be graduate student) Marilise Berrens. Dr Alexander Wandl (TUD BK), student assistant Barbara de Meijer (TUD BK) and Jamaal Tribune, MSc, will further support the team.

Awarded with the Convergence Resilient Delta Kick-Starter Grant

The Resilient Delta Initiative is a part of the Convergence, a partnership between TU Delft, Erasmus University Rotterdam, and Erasmus MC. The goal of the Convergence is to create new perspectives and solutions to tackle the urgent and complex societal challenges of our time. Resilient Delta focuses on the delta regions, “which are home to more than two-thirds of the world’s largest cities and are at risk from rising sea levels owing to their geographical location.” Resilient Delta is made up of a group of interdisciplinary researchers, all of whom collaborate with societal partners to design resilience solutions in the real-world dynamics of the Rotterdam delta.

Toward Textile-form Futures has received a €35,000 Convergence Kick-Starter Grant from Resilient Delta.

This blog is a partial repost of the article on TU Delft’s Industrial Design Engineering News.